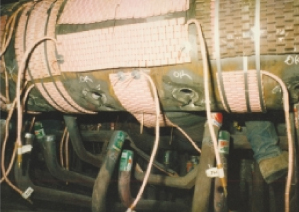

Phoenix Services is a technology leader in heat treating services. Having brought many new products to this field, we continue to innovate in ways that other companies cannot match. Our Management Team’s experience and knowledge in process, mechanical and metallurgical engineering insures safety, quality – focus and on-time project completion.

Our Heat Treating Teams have worked all over the world in refineries, petrochemical plants, gas plants, oil fields, offshore platforms, mines, power generating plants (nuclear, fossil and hydro), shipyards, metal processing and fabrication shops.

We offer the service and technology to match your heat treating requirements:

Turnkey Heat Treating Services

- Planning and Scheduling

- Mechanical Work

- Inspection

- Code Welding

- Commercial Evaluation

- Maintenance

Full Contract Service

- Preheat and Stress Relief of piping and pressure vessel welds

- Permanent Furnace

- La Porte, TX (10’ x 10’ x 10’)

- Gonzales, LA (10’ x 10’ x 10’)

- Temporary Field Furnaces

- Refractory Curing

- Curing of Phenolic and Paint Coatings

- Line Thawing

- Hydrogen Bake Outs

- B.H.N. Testing

Phoenix Services offers annual and/or job contract services for preheat and stress relief of piping, pressure vessels and fabrications, as well as shop heat treating for new construction, plant maintenance and metal fabrication.